Desiccant Dehumidifier

Our Desiccant Dehumidifier attract moisture from the air by creating an area of low vapor pressure at the surface of the desiccant wheel. The pressure exerted by the water in the air is higher, so the water molecules move from the air to the desiccant and the air is dehumidified.

Desiccant dehumidifier is energy efficient and effective if the treated room is both low in temperature and relative humidity. Typically, desiccant dehumidifier is recommended for treated room temperature at 22 deg. C and below, and to achieve humidity level at 40%RH and below. The Desiccant Dehumidifier is built with high quality components and material, to ensure that it operate effectively in all application that require to achieve low dew point.

Key Features

- The dehumidifier is equipped with High Performance Desiccant Rotor with high moisture adsorption rate for reliable performance and continuous trouble-free operation. Lifespan of the Rotor wheel is 5 – 8 years under normal operating condition (non-corrosive environment and regeneration temperature of below 140°C)

- Come with advance touch control panel with built-in Honeywell Temperature and Humidity Sensor for real-time monitoring, which is easy and user friendly to operate the dehumidifier.

- Our desiccant dehumidifier is built-in with high efficiency AC type or EC Centrifugal Fan to provide a smooth flow of process air. It is also come with separate fan for Regeneration Air.

- The dehumidifier is design with unique frame for better sealing and insulation structure to reduce heat loss.

- Body material of the dehumidifier is built with SPCC metal and Power-Coated paint for better resistant over corrosion.

- Built-in with reliable electrical component from well-known reliable brand. e.g. Schneider on the dehumidifier.

- Low operation cost and energy efficient. Our desiccant dehumidifier used PTC and SCR build heating technology with advance processor-controlled regeneration heat, which can save 20% -30% of power consumption.

- Structure of the dehumidifier is built for convenient installation and easy maintenance with replaceable filter and washable rotor. It is also build according Fire Prevention Standard, to ensure safe operation of the dehumidifier.

- Inlet and Outlet air of the dehumidifier is conformance to duct connection standard of ISO7807 to simplify air duct connection

- The dehumidifier is conformance to GS, ROHS and CE Standards.

Working Principle

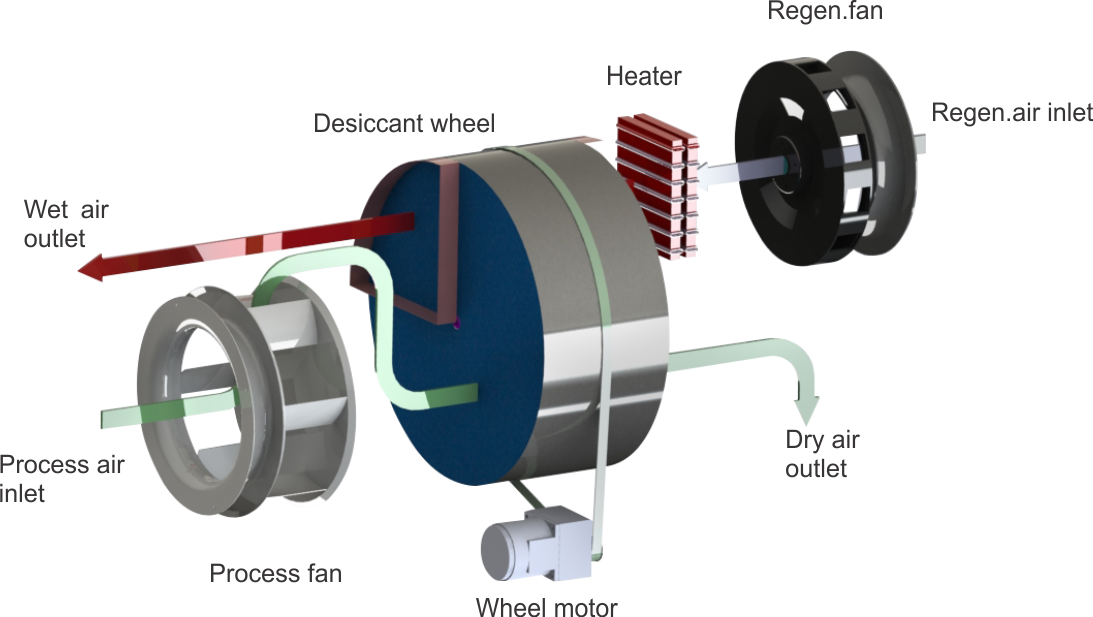

Our desiccant dehumidifier is developed to effectively treat applications that requiring low air humidity. The desiccant dehumidifier operates based on the adsorption principal. Treated air is simply passed through a porous wheel of solid desiccant and its moisture in the air is absorbed and the humidity level is lowered. After the wheel absorb the moisture, it will become saturates and in order to be used again it must be ‘recharged’ or also called as ‘regenerated’ by heating it up until the absorbed moisture is evaporated. The evaporated moisture will be driven off the desiccant wheel and goes right back to outdoor air or to surrounding ambient, which is not the treated room. The desiccant dehumidifier is designed so that the treated air is separated from the incoming air stream to dry the wheel, which will be exhausted to the outside.

The desiccant wheel is slowly rotating in the system to continuously absorb moisture to keep the treated air dry and regenerated using heater to help remove the absorb moisture from the desiccant. Roughly 3⁄4 of the time the desiccant will be absorbing moisture out of the treated room air, and the remaining 1⁄4 of the time it will recharge.